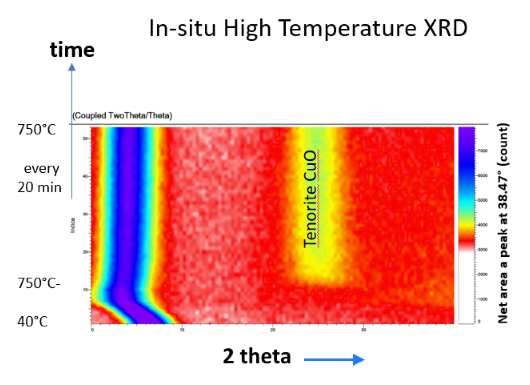

High Entropy (HE) materials

High-Entropy materials are characterized by multiple elements (≥5) that randomly occupy the same site in a crystal lattice, forming a single crystalline structure as a homogenous compound.

In 2004, the first High-Entropy (HE) Metal Alloys were discovered and more recently this was followed by oxides, carbides, nitrides and other compounds.

We have recently started to investigate some of these materials for energy conversion applications.

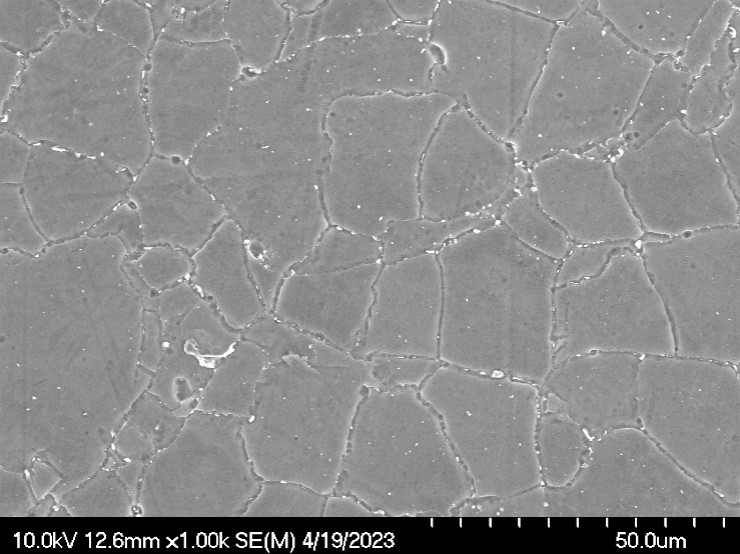

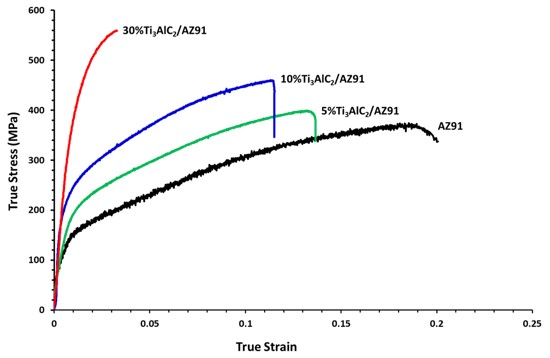

Reinforcement of lightweight magnesium alloys

Magnesium is a lightweight metal, making it an attractive choice for applications where weight reduction is crucial. Magnesium-based alloys are used in industries such as aerospace, automotive, and other lightweight manufacturing sectors.

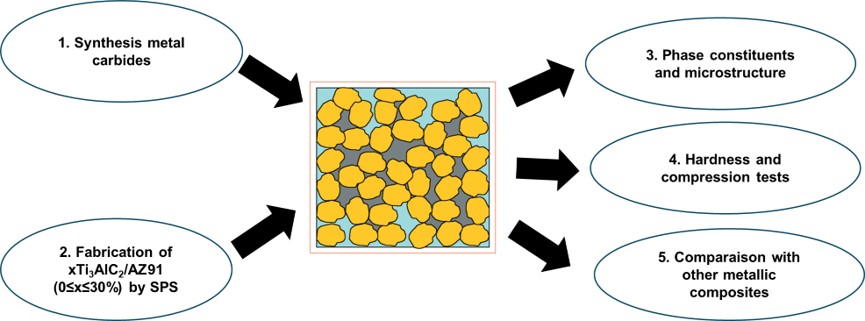

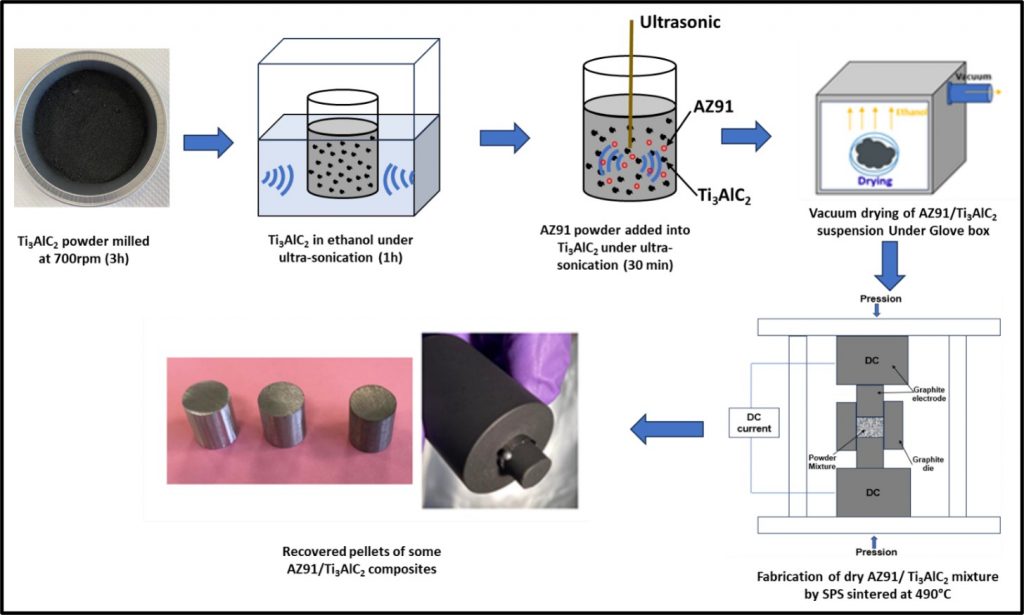

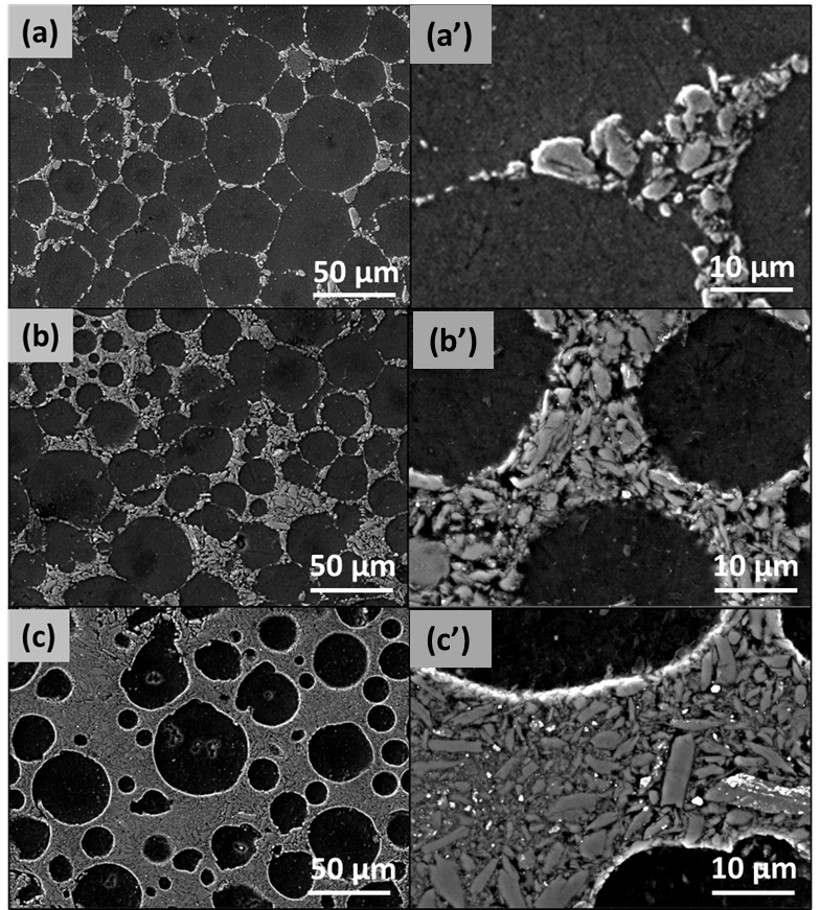

With academic partners, in the frame of France Relance program we are developing new composites based on Magnesium alloys and 2D metals carbides.